- Description

-

SUCCESS CASE

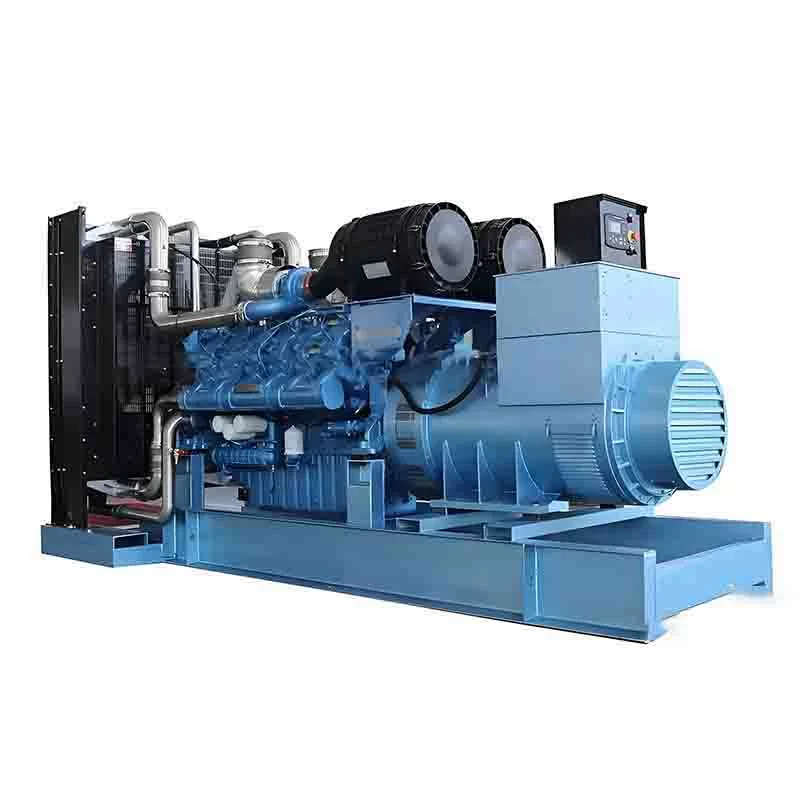

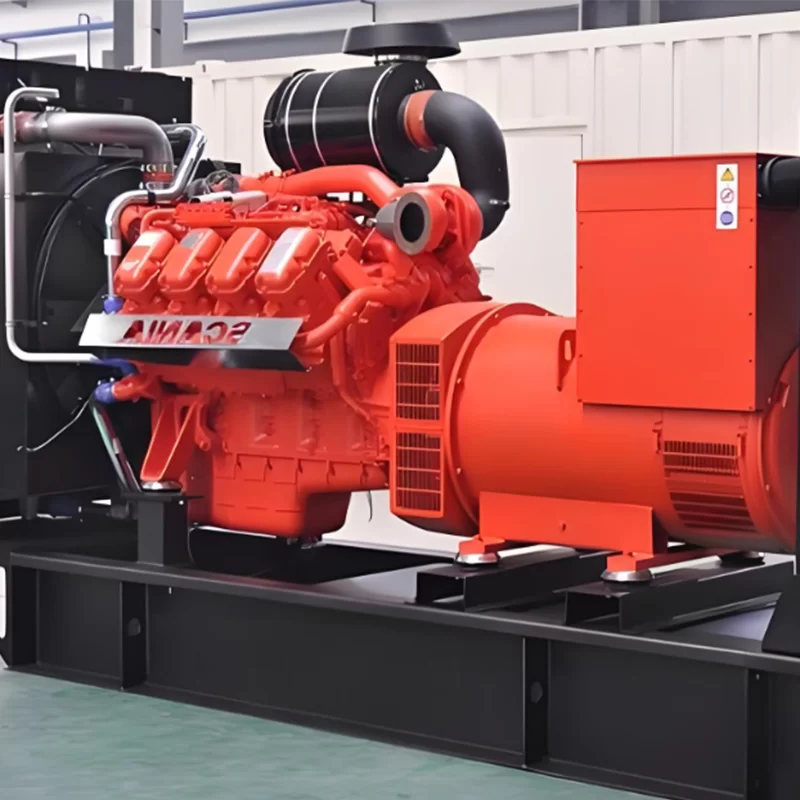

Jiangsu Kaichen Power Equipment Co., Ltd. meets global customers' needs with a scalable approach—from standard and modular designs to fully customized systems. Its core market advantages include reliable performance in diverse settings, improved fuel economy, smart automation, and internationally recognized certifications.

Africa Data Center – Critical Backup Power Supply

Africa Data Center – Critical Backup Power SupplyData centers across much of Africa confront operational threats from grid instability, repeated power failures, and voltage swings, which can lead to data corruption and service interruption. For a Lagos‑based commercial data center needing uninterrupted server operation, we supply “sound‑proofed container power stations.” These all‑in‑one units encapsulate the genset, control panel, fuel tank and cooling in a noise‑controlled container, providing robust and quiet power for data‑center loads. The integrated remote monitoring system enables real‑time surveillance and predictive maintenance from any location, including China.

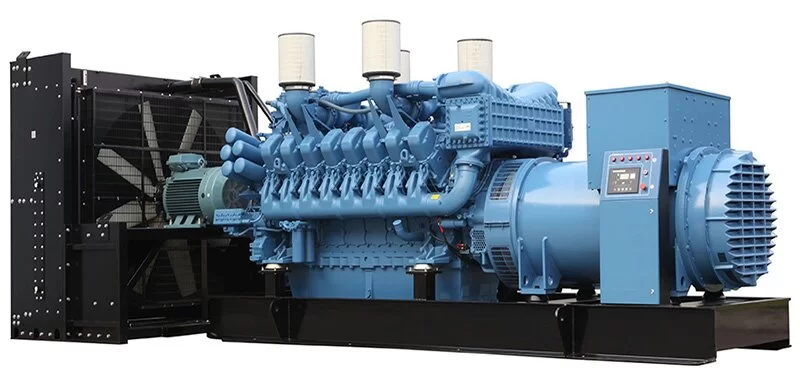

Middle Eastern construction sites – main power supplyRemote desert infrastructure projects typically lack access to utility power. Construction equipment—tower cranes, concrete mixers, welding tools—and living quarters require dedicated power generation. We provide heavy-duty generators designed to resist dust and intelligent paralleling technology. Tailored for high-temperature, sandy environments, these units include high-performance air filters and ample cooling capacity. The control system automates parallel operation and load balancing among several generators, yielding notable savings in fuel and maintenance.

Middle Eastern construction sites – main power supplyRemote desert infrastructure projects typically lack access to utility power. Construction equipment—tower cranes, concrete mixers, welding tools—and living quarters require dedicated power generation. We provide heavy-duty generators designed to resist dust and intelligent paralleling technology. Tailored for high-temperature, sandy environments, these units include high-performance air filters and ample cooling capacity. The control system automates parallel operation and load balancing among several generators, yielding notable savings in fuel and maintenance. South Asian Agriculture and Aquaculture – Power Sources

South Asian Agriculture and Aquaculture – Power SourcesStable electrical supply is crucial in farming for irrigation pumping, grain processing, and large‑scale aquaculture aeration and cooling. However, inadequate grid infrastructure or frequent power fluctuations in these areas can reduce crop harvests and aquaculture survival rates. We provide generator sets that are both affordable and built to last, with an emphasis on dependability, ease of use, and reduced maintenance. Our support includes illustrated, multilingual handbooks and basic video‑based training for local operators, promoting reliable, long‑term service in agricultural environments.

Southeast Asian Island Resort – Lone Grid Power Supply

Southeast Asian Island Resort – Lone Grid Power SupplyBuilding a tourist resort on an island with no power grid necessitates a self-sufficient energy system. It must generate electricity 24 hours a day for all guest facilities, food services, water desalination, sewage management, and climate control installations.

For standalone power systems, a microgrid can be built around diesel generator sets. Multiple gensets are typically operated in parallel to supply the base electrical load. In order to decrease the high cost and logistical challenges of diesel supply, as well as limit noise, many projects now combine solar photovoltaic arrays to form a hybrid system, where generators are used only when solar power is insufficient or during peak usage.

Core Advantages

Core AdvantagesExceptional Reliability: With cutting-edge diesel engines and superior alternator components, our generators offer accelerated activation and sustained power reliability in high-pressure operational situations.

Superior Fuel Efficiency: High-efficiency engine technologies coupled with adaptive control frameworks ensure optimal fuel utilization, reducing both operational expenditure and environmental burden.

Robust Durability: Utilizing rugged components and optional protective exteriors, our power systems are built to perform under extreme conditions, offering exceptional durability.

Low Maintenance & User-Friendly: Designed for quick servicing through logical layout and accessibility, the system lowers downtime. Control panels are easy to navigate with automated support, streamlining operation and monitoring.

Technical Highlights

Technical HighlightsPower Range: Available across the 20–2500 kVA spectrum, these generators can meet differing power requirements.

Advanced Control Systems: Real-time oversight of electrical output, fuel levels, and system diagnostics is provided through a unified digital control panel. Optional AMF modules ensure automatic and smooth power transfer during utility loss.

Embedded Safety Controls: Offers protection functions for overload, short circuit, dropping oil pressure, and rising coolant temperature.

Certification-Oriented Manufacturing: Follows globally accepted quality procedures and allows customization to match emission and safety statutes.

Application AreasKaichen diesel generator sets are utilized where dependable power is non-negotiable:

Application AreasKaichen diesel generator sets are utilized where dependable power is non-negotiable:Commercial & Infrastructure: For data halls, emergency care units, network towers, shopping districts, and business parks.

Industrial: In assembly lines, resource extraction zones, building developments, and purification stations.

Utility & Events: As primary supply in rural setups, emergency backup for municipal services, and temporary grids for outdoor events.

Commitment

CommitmentKaichen regards power as a covenant, not merely an output. We commit to designing resilient, efficient, and smart power generation systems that ensure your operations proceed without disruption.

FAQ

FAQQ1: What are your key products and their application areas?

A1: We supply diesel engine systems (4/6/12 cylinder) and complete power generation sets. These serve global markets in electrical power production, industrial water management, agricultural mechanization, maritime industries, construction sectors, and specialized vehicle applications.

Q2: What is your standard manufacturing lead time?

A2: Regular inventory supports fast order processing. Customized productions utilize our material reserves to shorten lead times, typically delivering within 7-10 days. Production schedules may vary according to technical specifications.

Q3: What is the delivery schedule after order confirmation?

A3: Stock items dispatch immediately. Custom orders enter production rapidly with our material availability. For quantities under 100 units, manufacturing completes in 7-10 days, with ocean transportation requiring 20-60 days depending on destination.

Q4: What's your MOQ?

A4: 1 set

-

-